The Five-Stage Milking Machine Cleaning Process

Rinse – Alkaline Wash – Acid Rinse – Sanitize – Dry: Purpose, Sequence Logic, and Timing

A validated five-stage protocol removes milk residues, pathogens, and mineral buildup while extending equipment lifespan. The sequence follows chemical compatibility principles—each step prepares the surface for the next while preventing damage or recontamination.

Dairy-Specific Detergent Guidelines: Temperatures, Concentrations, and Product Selection

Alkaline detergents require a precise 2.5 mL/L concentration at 71–77°C to hydrolyze milk fats without degrading rubber seals. Acidic solutions must operate within pH 3.0–4.0 to dissolve calcium and magnesium deposits effectively. Three detergent categories address distinct challenges:

- High-alkaline formulations target stubborn protein and fat residues

- Nitric-acid blends prevent milkstone formation in hard-water regions

- Chlorine-based sanitizers deliver rapid, broad-spectrum bacterial reduction (99.9%)

Temperature deviations beyond ±5°C reduce cleaning efficacy by 30–45%, per research published in the Journal of Dairy Science. Titration testing every 500 cleaning cycles ensures consistent dosing, while water hardness assessment guides product selection to avoid premature gasket swelling or cracking.

System-Specific Cleaning Protocols for Milking Machine Types

Pipeline vs. Bucket Systems: Preventing Biofilm in Stainless Steel and Rubber Components

Controlling biofilms requires tailored approaches for different systems. For buckets, taking apart all those parts like liners, gaskets and valves manually comes first before scrubbing with hot alkaline solutions. The reason? Those tiny cracks in old rubber create perfect spots for biofilms to hide out. Pipeline systems present their own challenges too. During Clean-in-Place cycles, keeping the flow really turbulent matters a lot. Temperatures need to hit at least 120 degrees Fahrenheit at the discharge end to stop milk solids from settling back down. What connects these setups? They both have trouble spots nobody wants to think about. Stainless steel welds and joints tend to collect proteins that protect bad bacteria, and rubber parts just get worse with age, creating more nooks and crannies where problems can start.

A 2023 sanitation study found bucket systems showed 32% higher bacterial recurrence when components were not inverted for full drainage after drying—highlighting the importance of air-drying orientation. Thermal validation of alkaline wash temperature at critical points remains the most reliable predictor of long-term milkstone prevention across both designs.

Bulk Tank Sanitization: Frequency, Thermal Stability, and Post-Cleaning Residue Testing

Bulk tanks must be sanitized after every milk collection using thermally stable agents effective above 140°F. Industry standards—including the National Mastitis Council and FDA Grade “A” Pasteurized Milk Ordinance—mandate weekly deep-cleaning cycles with acid rinses to remove mineral scale, verified via ATP swab testing.

Detergent performance declines by 18% per 10°F below optimal temperature, underscoring the need for calibrated temperature sensors at tank inlets and outlets. Post-cleaning verification includes:

- Triple-rinse conductivity tests to detect alkaline carryover

- Final rinse water pH ≤6.5 (measured at outlet)

- Visual inspection for water beading, indicating hydrophobic residue films

Monthly surface bacterial cultures provide longitudinal assurance; coliform counts exceeding 100 CFU/cm² trigger full system revalidation and root-cause analysis.

Critical Milking Machine Maintenance Tasks and Schedules

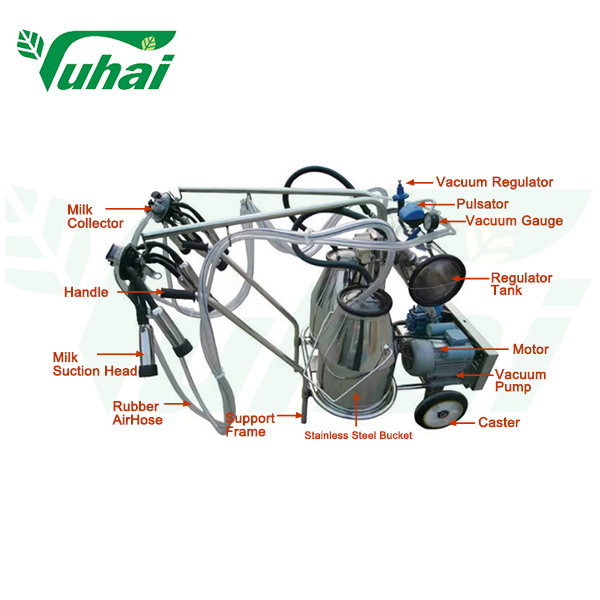

Pulsator Calibration, Vacuum Regulator Checks, and Gasket Replacement Intervals

Regular maintenance work has a direct impact on milk quality, how well animals are treated, and how long equipment lasts before needing replacement. When it comes to pulsators, they need to be calibrated either once a month or every other month based on how heavily they're used. This helps maintain consistent pulsation rates throughout the process. If the cycling gets irregular, that can lead to problems at the teat end and also makes milk extraction less efficient overall. For vacuum regulators, farmers should check these things weekly to make sure the pressure stays within the proper range of around 42 to 50 kilopascals. Pressure that's too high or too low causes issues like liner slippage during milking, leaves some milk behind in the udder, or even damages sensitive tissues. And don't forget about those gaskets either. They typically need replacing after about 1,200 milkings or roughly every six months, whichever happens first. Fresh gaskets stop bacteria from getting into the system through worn out seals located in the claws, liners, and housing units of the milking clusters.

Balancing Milk Safety, Cleaning Efficacy, and Milking Machine Longevity

Evidence-Based Tradeoffs: Alkaline Wash Frequency vs. 3-Year Component Wear (YUYAO YUHAI Field Study, 2023)

Washing equipment daily with alkaline solutions gives the best microbial control, but it comes at a cost to important parts over time. Research from 2023 looked at 42 dairy farms across the country and saw something interesting happen. The daily cleaning schedule actually cut down the lifespan of those pulsator diaphragms and rubber liners by around 15% when compared to cleaning every other day. And guess what? The milk still met all the regulations for bacteria levels (under 10,000 CFU/mL) so there wasn't really any benefit in terms of safety. What researchers noticed though was that the gaskets started getting harder faster, and tiny pits began forming on stainless steel surfaces after being exposed to high pH conditions constantly. These effects build up gradually but can lead to bigger problems down the road if not monitored carefully.

According to recent research, mid sized dairy farms might want to try combining different cleaning methods. After the morning milking session, doing a complete alkaline wash makes sense. Then when collecting milk in the evenings, switch to targeted acid rinses instead. Farmers who followed this routine saw their equipment last longer, with about 11 percent less wear on components after three years. Plus they stayed within all the required milk safety standards across the country. These include important guidelines from groups like the International Dairy Federation as well as Codex Alimentarius. For many dairy operators concerned about both costs and quality control, finding such practical solutions can make a real difference in daily operations.

FAQ

What is the primary purpose of stage-wise cleaning in milking machines?

Stage-wise cleaning is designed to remove milk residues, pathogens, and mineral build-up while extending equipment lifespan. Each cleaning stage prepares surfaces for the next while preventing damage or recontamination.

Why is immediate rinsing important after milking?

Immediate rinsing prevents protein denaturation on stainless steel surfaces and reduces chances of irreversible milkstone accumulation.

How frequently should bulk tanks be sanitized?

Bulk tanks should be sanitized after every milk collection and undergo weekly deep-cleaning cycles with acid rinses per industry standards.

Why does components wear out faster with daily alkaline washing?

Daily alkaline washing provides excellent microbial control but expedites wear on pulsator diaphragms and rubber liners due to constant exposure to high pH conditions.