Understanding the Key Types of Cow Milking Machines and Their Automation Levels

From Hand Milking to High-Tech Automation: Evolution of the Cow Milking Machine

What used to be all hands on deck for milking cows has changed completely over time. Back in the late 1800s farmers started using basic mechanical devices, though it wasn't until vacuum systems came along that things really took off these systems worked kind of like how calves naturally nurse. Today's farms are seeing another big shift toward fully automated setups where robots do most of the work. These modern systems combine robotic arms, various sensors throughout the barn, and even some level of AI to handle milking tasks while humans monitor from afar. Farmers across the globe keep pushing forward because they want their operations to run smoother, treat animals better, and scale up production without breaking a sweat.

How Bucket, Pipeline, and Robotic Milking Systems Differ in Design and Function

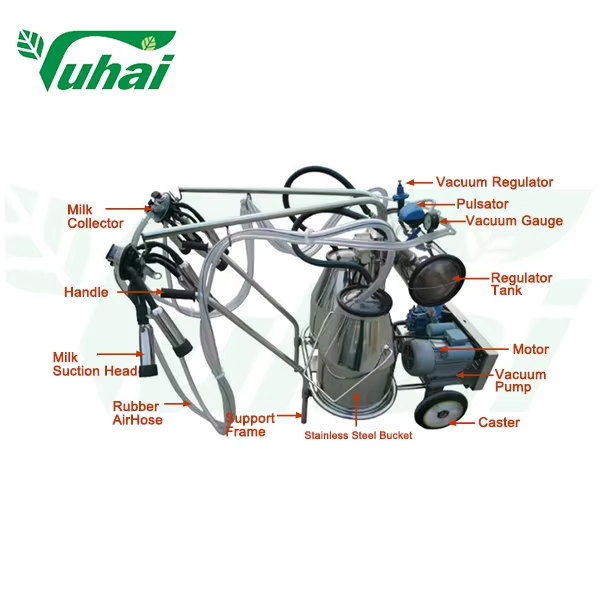

There are basically three main types of cow milking machines, each working differently depending on what kind of operation they're used in. Bucket systems are these portable setups where milk goes straight into a closed container. They work best for smaller herds or when cows are out grazing most of the day. Then there's pipeline systems which run milk right from the parlour to a big storage tank through those metal pipes that stay put. These cut down on all the back and forth handling needed, so they're pretty popular among midsize dairy farms. The newest option though is robotic milking systems, often called RMS for short. These high tech contraptions let cows decide when they want to be milked. The robots can spot individual animals, clean up around them, hook themselves on, and even keep track of how each cow is doing throughout the process. What works best really depends on how many cows someone has, how much time they want to spend managing things, and whether they care about collecting detailed data on milk production or not.

Matching Farm Goals to Milking Technology: A Strategic Approach

Picking the right milking machine for cows means matching tech options with what the farm actually needs. For operations where saving on labor matters most and managers want all sorts of data about their herd, those fancy robotic systems can definitely pay off despite costing more at first. They cut down on work hours and give farmers detailed info about each cow's performance over time. On the flip side, smaller farms or those just starting out often go with simpler setups like buckets or pipelines instead. These systems aren't as high tech but still save a lot compared to doing everything by hand. When making this choice, think about how many cows there are now, who does the milking work currently, whether the business plans to grow bigger soon, and how comfortable everyone is with adopting newer technologies. What works today might not fit tomorrow's plans, so finding something flexible enough to handle changes makes sense in the long run.

Cost Analysis of Cow Milking Machines: Upfront Investment vs. Long-Term ROI

Initial Costs Compared: Bucket, Pipeline, and Robotic Milking Systems

How much money farmers need to spend on a cow milking machine depends heavily on what kind of system they choose. The simplest option is basic bucket systems which are cheapest to get started with since they don't require much in terms of setup. Pipeline systems offer better efficiency but come at a price because they need dedicated milking parlors and all those pipes running everywhere. Then there's robotic milking systems that cost a fortune upfront. We're talking around $150k to $230k per unit according to some industry reports from last year. That big number doesn't just cover the robots themselves either. Farmers have to modify their barns, pay for installation work, and train everyone involved including the cows who might be confused at first when machines start doing their milking instead of humans.

Long-Term Return on Investment: When Robotic Systems Pay Off

Robotic systems might cost a pretty penny upfront but often pay off over time for many dairy operations. The biggest money saver comes from cutting down on labor needs. Research shows farms using robotic milking systems typically cut their labor costs around 32%, according to a study from Ponemon in 2023. There are other benefits too. Cows tend to produce more milk when they get milked more regularly and consistently. Plus, farmers notice better feed efficiency because these systems track everything so precisely. On bigger farms with hundreds of cows, combining those labor savings with increased production usually means the investment pays for itself somewhere between 3 and 5 years. That makes sense for dairy farmers planning ahead who want to scale their operations while keeping costs under control.

Labor Efficiency and Operational Impact Across Milking System Types

Reducing Labor Dependency with Automated Cow Milking Machines

Cow milking robots cut down on the need for farmhands compared to old school methods, with some operations reporting around three quarters less labor needed for milking. According to studies from the Journal of Dairy Science back in 2016, farms equipped with these automatic milking systems spend just over two hours per cow each year on milking duties, whereas traditional setups take nearly eight hours per animal. This massive time savings means dairy farmers can shift their workforce toward more important tasks like keeping tabs on cow health, managing pastures better, and fine tuning overall farm operations. Plus, automated milking takes a lot of the physical toll off workers while giving them more control over their schedules. Of course, there's still a learning curve involved since these systems demand technical know how instead of brute strength.

Does Less Labor Mean Better Efficiency? Balancing Output and Oversight

Robotic milking systems cut down on hands-on labor but bring their own set of challenges that impact how well things run day to day. These automated setups let farmers milk cows two or three times a day without needing extra help, something that typically boosts each cow's output around 5 to maybe even 10 percent. But getting those gains means keeping tabs on regular maintenance, watching all that data coming from the machines, and making sure cows move through the system properly. Farms that really succeed find ways to mix lower staffing needs with better supervision. They tap into what modern milking tech offers in terms of data collection to figure out what's working for their herd and where resources should go first.

Farm Size and Scalability: Choosing the Right Cow Milking Machine for Your Operation

Best Milking Systems for Small, Medium, and Large-Scale Dairy Farm Automation

Choosing a cow milking machine really comes down to how big the farm is and what kind of management approach makes sense for the herd. Family farms with around 20 to 50 head usually get along just fine with basic bucket setups or individual units since they don't require much upfront cash and are easy enough to operate day to day. When operations grow to between 50 and 200 cows, many farmers turn to pipeline systems because these strike a good middle ground between getting through more milk and keeping labor demands at reasonable levels. Big commercial dairies with over 200 cows tend to go for automated robotic systems that can scale up production while allowing for round the clock milking without needing so many hands on deck all the time. According to industry reports, roughly seven out of ten large dairy operations see their money back invested in robotic systems within about five years thanks mainly to better milk output and cutting down on payroll costs.

Future-Proofing Your Dairy: How Scalability Influences Machine Choice

Investing in a milking machine isn't just about what the farm needs right now it's also about where things might go in the coming years. Pipeline setups can handle some growth by adding more units here and there, but robotic systems really shine when herds expand because they don't require hiring extra hands as numbers grow. Look at actual farm data from across the country shows operations that thought ahead about scaling their operations ended up spending around 30 percent less on replacing equipment after ten years. There are several important factors worth thinking about before making this big purchase decision.

- Herd growth projections

- Available infrastructure space

- Compatibility with emerging monitoring technologies

- Ease of integrating additional units or software updates

Strategic planning ensures your milking system grows with your operation, protecting long-term productivity and investment value.

Milk Yield, Cow Welfare, and Data Integration in Modern Milking Systems

How Milking Machine Type Affects Milk Yield and Herd Health

Choosing the right milking equipment makes a real difference for milk output and animal well being across dairy operations. Robotic systems let cows follow their own rhythm for milking sessions throughout the day, something that cuts down on stress levels and often boosts total production numbers. Farmers who switched to these automated setups have seen some impressive results too, with annual yields jumping anywhere between seven thousand liters all the way up past nine thousand liters per head. From a health standpoint, newer models incorporate soft vacuum cycles similar to how a calf would nurse naturally, significantly cutting down cases of mastitis and other common issues. The sealed pipelines found in many contemporary installations keep everything cleaner during transport as well, preserving milk quality while protecting sensitive udder tissue against contamination risks.

Cow Comfort and Stress Reduction: Advantages of Robotic Milking

When it comes to cow comfort, robotic milking systems really make a difference because they let the animals decide when they feel like being milked. This kind of on-demand milking cuts down stress levels quite a bit compared to those old school fixed time systems, which helps keep the cows happier and maintains good milk production over time. Most robotic setups come equipped with gentle, adaptable parts that fit different body types plus lighting that's not too bright or harsh, so the whole process isn't so scary for the herd. Less stressed out cows tend to stay healthier overall, suffer fewer injuries during milking sessions, and produce milk at a steadier rate throughout the day. These advantages matter a lot in today's dairy farms where efficiency and animal well-being go hand in hand.

FAQ Section

How do robotic milking systems benefit dairy farms?

Robotic milking systems offer benefits such as reduced labor costs, increased milk yield, improved cow welfare, and better data collection for monitoring herd health.

Are robotic milking systems worth the investment?

While robotic systems require significant upfront investment, the long-term return can include labor savings and improved milk production, especially for larger farms.

How can farms choose the right milking system?

Farms should consider factors like herd size, management goals, and scalability when choosing the right milking system to meet their current and future needs.

What are the main types of cow milking machines?

There are three main types of cow milking machines: bucket, pipeline, and robotic systems. Each has its own design and function tailored to different farm needs.

Table of Contents

- Understanding the Key Types of Cow Milking Machines and Their Automation Levels

- Cost Analysis of Cow Milking Machines: Upfront Investment vs. Long-Term ROI

- Labor Efficiency and Operational Impact Across Milking System Types

- Farm Size and Scalability: Choosing the Right Cow Milking Machine for Your Operation

- Milk Yield, Cow Welfare, and Data Integration in Modern Milking Systems

- FAQ Section