Why Regular Cleaning of Your Goat Milking Machine Matters

Proper cleaning of your goat milking machine isn't just a chore—it's essential for producing safe, high-quality milk. Neglecting this critical task can lead to serious consequences for both your dairy operation and consumers.

Impact of improper cleaning on milk quality and safety

If dairy farmers don't clean their milking gear thoroughly after each use, leftover milk starts building up inside the machines. What happens next? Well, those residues become perfect spots where bacteria love to multiply. The consequences aren't just unpleasant tasting milk either. Milk stays fresh for shorter periods when contaminated this way, and worse still, dangerous germs find their way into what ends up on supermarket shelves. Research published in Food Safety Journal back in 2023 found something alarming too poor cleaning practices actually boost bacterial levels in milk processing systems by around three times normal amounts. That kind of jump doesn't just affect quality standards it shakes consumer confidence completely when people wonder if their morning cereal is really safe to eat.

How hygiene prevents bacterial contamination in goat milk

Getting rid of those organic residues through proper cleaning stops bacteria from getting a foothold and growing out of control. After every milking run, it's really important to sanitize everything thoroughly because otherwise biofilms start forming on surfaces. These slimy little colonies of microbes stick around and keep contaminating the milk supply over time. Stick to the recommended cleaning procedures for all dairy equipment and the goat milk stays fresh longer, remains safe for consumption, and doesn't get tainted by dangerous microorganisms lurking in corners where we can't see them.

Regulatory standards and recommended cleaning frequency for milking equipment

Food safety agencies across the country insist that milking gear gets cleaned thoroughly after each session. According to USDA guidelines, dairy operations must run through three steps: first rinse, then wash with proper detergents, followed by thorough sanitization prior to the next milking round. State regulations vary quite a bit, though most demand at least daily cleaning as baseline practice. Keeping up with regular maintenance does more than just satisfy inspectors it actually pays off in the long run. Equipment lasts longer when properly maintained, which means fewer replacement costs down the road for farm owners who take care of their machinery right from day one.

Daily Cleaning Routine for Optimal Goat Milking Machine Performance

Proper daily cleaning is essential for maintaining both milk quality and equipment longevity. A consistent post-milking routine prevents bacterial growth and ensures your goat milking machine operates at peak performance.

Step-by-step post-milking cleaning process for your goat milking machine

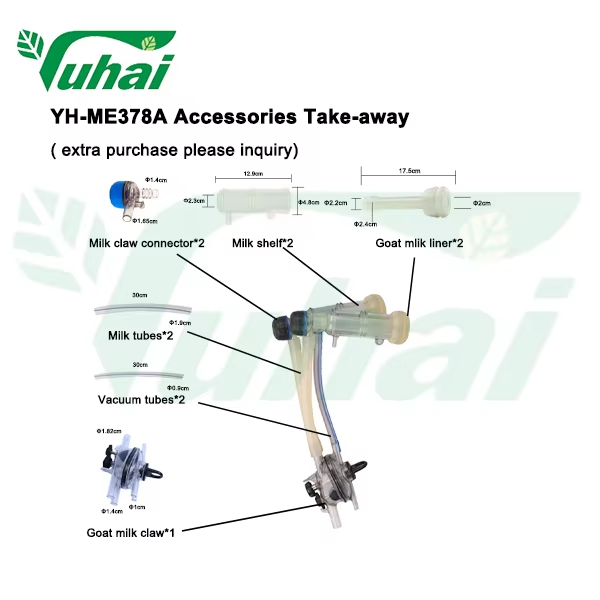

Get those parts rinsed off right away with some lukewarm water around 100 to 110 degrees F to get rid of any milk left behind. Take everything apart - those claw attachments, inflation devices, plus all those milk lines running through the system. Wash each individual component separately with proper dairy cleaning solution and make sure to have a special brush just for this job. After giving them a good rinse under warm water, it's time for something important but not so pleasant looking: apply that acid based sanitizer stuff. This helps stop those pesky mineral deposits from forming and keeps microbes at bay too. Most experienced workers know this step makes all the difference in keeping equipment working properly long term.

Importance of immediate cleaning: Preventing residue buildup after each use

Getting those milking equipment cleaned within about half an hour stops proteins and fats from turning into stubborn gunk that sticks around. If farmers wait too long, bacteria start multiplying fast. According to dairy industry standards, germ levels can jump almost three times higher just one hour after milking. Cleaning promptly makes a real difference when it comes to stopping biofilms before they take hold. Trust me, trying to clean established biofilms later on is way harder work than preventing them in the first place.

Using a claw washer and best practices for sanitizing machine surfaces

Claw washers boost cleaning effectiveness because they pump cleaning solution into those tricky spots inside equipment where fingers just can't get. To get the most out of these systems, operators should stick with USDA approved sanitizing agents mixed properly. The concentration usually needs to be around 100 to 200 parts per million of either chlorine or iodine. Letting the sanitizer stay on surfaces for about half a minute makes all the difference. This final touch really helps knock out any lingering bacteria that might have survived the initial rinse, which is especially important in food processing environments where contamination risks remain high even after basic cleaning procedures.

Cleaning the milking area: Floors, buckets, and surrounding surfaces

Sanitation must extend beyond the machine. Clean buckets and collection containers with the same rigor as milking equipment. Regularly disinfect floors, walls, and nearby surfaces to minimize environmental contamination. Combine thorough cleaning with proper ventilation and dry storage conditions to significantly reduce microbial risks in the milking parlor.

Weekly Deep Cleaning and Maintenance of Goat Milking Equipment

Beyond daily washing: Establishing a weekly maintenance schedule

While daily cleaning handles fresh residues, weekly deep cleaning targets accumulated minerals and hidden biofilms. Schedule a comprehensive session—such as every Sunday after milking—to fully disassemble, inspect, and sanitize all components. This proactive rhythm ensures long-term hygiene and mechanical reliability.

Acid rinses and enzymatic cleaners to prevent milk stone and bacterial growth

Weekly acid rinses work wonders for getting rid of those calcium and magnesium deposits we call milk stone. Phosphoric or nitric acids are good options for this job. But don't stop there. These acid treatments should be combined with enzymatic cleaners that tackle those tough fats and proteins stuck on surfaces. Some studies indicate that if surfaces aren't properly maintained, biofilms can come back within just three days. That's why sticking to a regular schedule of weekly treatments really matters when it comes to keeping bacteria levels under control long term.

Inspecting hoses, liners, valves, and gaskets during deep cleaning

During disassembly, closely examine rubber and silicone parts for cracks, stiffness, or discoloration. Replace worn liners promptly, as degraded elasticity disrupts vacuum balance and increases mastitis risk. Check valve membranes and gaskets for integrity to maintain airtight seals. Tracking wear patterns helps anticipate replacements and avoid unexpected breakdowns.

Best practices for stainless steel milking equipment longevity

Following acid treatment, it makes sense to rinse stainless steel parts using water that has a neutral pH level to stop any corrosion from happening later on. Soft bristle brushes work best here since harsher ones might scratch away at the metal surface which protects against rusting. After everything is clean and sanitized properly, let all these pieces dry thoroughly in the air before putting them back together again because leftover moisture tends to create problems with bacteria growing back over time. When someone takes the trouble to give their gear regular maintenance once every week or so, they'll find that good quality equipment actually lasts about forty percent longer compared to when people just do minimal cleaning routines now and then.

Preventing Long-Term Damage and Ensuring Sanitation Compliance

Avoiding corrosion and pitting in stainless steel components through proper rinsing

Leftover minerals from water and cleaning products will eat away at stainless steel when they aren't properly washed off. When there's not enough rinsing, small pits start forming on surfaces, particularly noticeable around those hard to reach corners and welded areas. Machines that get cleaned improperly tend to break down about 40 percent quicker over time according to industry observations. The best practice? Finish every cleaning session with a good soak in warm running water. This helps balance out chemical residues and keeps the metal strong for longer periods between maintenance checks.

Maintaining sanitation beyond the machine: Stalls, collection systems, and worker hygiene

Good sanitation isn't just about cleaning machines but covers everything in the milking area. From where animals rest to how milk moves through pipes and what workers do during handling, each factor affects whether milk stays safe. Most contamination actually comes from places beyond equipment itself, like when cows have muddy udders, staff members touch things without washing their hands first, or wear clothes that aren't properly cleaned. Farmers should set some basic hygiene standards though. Everyone needs to wash their hands regularly, put on fresh shoes before entering barns, and wear gear that's been properly disinfected. Research indicates following these simple steps can cut down bacteria spread by around 80 percent, which makes a big difference for maintaining high quality standards across dairy operations.

Aligning goat milking machine maintenance with food safety regulations

Maintaining equipment regularly helps meet FDA CGMP requirements that mandate written cleaning protocols and proof that sanitation actually works. For dairy plants specifically, taking good care of machinery is essential if they want to stay within regulatory boundaries and protect their certification standing. Dairy processors need to track everything from when tanks get cleaned to inspection dates and any repair work done. These records serve as evidence of proper maintenance practices and show genuine concern for keeping food safe throughout production processes.

FAQ

How often should the goat milking machine be cleaned?

The goat milking machine should be cleaned thoroughly after each milking session as per USDA guidelines, to ensure milk safety and quality.

What cleaning agents are recommended for goat milking machines?

Proper detergents, acid-based sanitizers, and USDA-approved sanitizing agents like chlorine or iodine at proper concentrations are recommended.

Why is it important to sanitize all dairy equipment?

Sanitizing dairy equipment prevents bacterial growth and biofilm formation, ensuring that milk stays safe for consumption and free from contamination.

Can improper cleaning lead to equipment damage?

Yes, improper cleaning can lead to residue buildup, corrosion, and pitting in equipment, decreasing its longevity and efficiency.

What additional sanitation measures should be followed in the goat milking machine area?

Along with machine cleaning, disinfect floors, walls, and milking areas regularly and ensure worker hygiene to minimize microbial risks.

Table of Contents

- Why Regular Cleaning of Your Goat Milking Machine Matters

- Daily Cleaning Routine for Optimal Goat Milking Machine Performance

- Weekly Deep Cleaning and Maintenance of Goat Milking Equipment

- Preventing Long-Term Damage and Ensuring Sanitation Compliance

-

FAQ

- How often should the goat milking machine be cleaned?

- What cleaning agents are recommended for goat milking machines?

- Why is it important to sanitize all dairy equipment?

- Can improper cleaning lead to equipment damage?

- What additional sanitation measures should be followed in the goat milking machine area?